At Intel Foundry Direct Connect 2025, Intel outlined advancements in its process technologies, packaging solutions, U.S. manufacturing efforts, and ecosystem collaborations. The event focused on technical updates and partnerships to address semiconductor industry needs.

Process Technology Developments

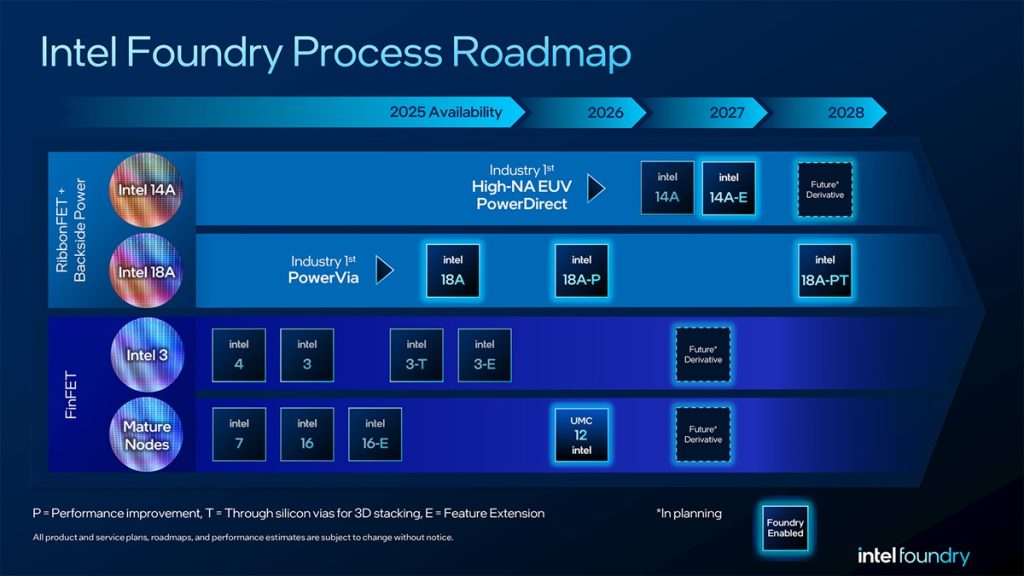

Intel discussed its Intel 14A process, the next step after Intel 18A. It shared early Intel 14A Process Design Kits (PDKs) with key customers, who plan to create test chips. Intel 14A uses PowerDirect for direct power delivery, building on Intel 18A’s PowerVia technology.

Intel 18A is in risk production and set for volume manufacturing in 2025. Intel’s ecosystem collaborators have created electronic design automation tools, reference flows, and intellectual property for manufacturing.

A variant, Intel 18A-P, targets better performance for more customers, with early wafers in fabrication. As it’s compatible with Intel 18A design rules, partners are updating their tools for Intel 18A-P.

Another variant, Intel 18A-PT, improves performance and efficiency. It supports Foveros Direct 3D stacking with a hybrid bonding pitch under 5 micrometers. Intel also started its first 16nm production tape-out and is working with UMC on a 12nm node and related variants.

Advanced Packaging Solutions

Intel detailed packaging options, including Intel 14A on Intel 18A-PT with Foveros Direct (3D stacking) and embedded multi-die interconnect bridging (2.5D bridging).

Intel introduced EMIB-T to support high-bandwidth memory needs, alongside Foveros-R and Foveros-B variants for adaptable designs, and collaborated with Amkor Technology to assist customers in choosing suitable packaging solutions.

U.S. Manufacturing Progress

Ecosystem Collaborations

Intel expanded its Accelerator Alliance with the Intel Foundry Chiplet Alliance, focusing on secure chiplet solutions for government and commercial uses, and the Value Chain Alliance, which supports supply chain collaboration. Other alliances include IP, EDA, Design Services, Cloud, and USMAG. These programs provide tools and IP to support customer designs, Intel said.

CEO Lip-Bu Tan stated, “Intel is building a world-class foundry to meet the growing need for leading-edge process technology, advanced packaging, and manufacturing.” Naga Chandrasekaran, Chief Technology and Operations Officer, and Kevin O’Buckley, General Manager of Foundry Services, gave keynotes on process, packaging, and global supply chain updates.

At the event, Intel CEO Lip-Bu Tan said:

Our No. 1 job is to listen to our customers and earn their trust by creating solutions that support their success. The work we are doing to build an engineering-first culture across Intel, while deepening our partnerships throughout the foundry ecosystem, will help us advance our strategy, improve execution, and succeed in the long term.