Apple has announced a new goal to speed up its use of recycled materials in its products, with a 2025 deadline to make all Apple-designed batteries from 100 percent recycled cobalt.

This is part of Apple’s increased efforts to reuse gold, tungsten, cobalt, and other elements in its products, which it started last year.

Apple’s Progress towards Sustainable Materials and Packaging Goals

Recycled Metals: In 2022, Apple expanded its use of recycled metals, with over two-thirds of aluminum, nearly three-quarters of rare earths, and over 95 percent of tungsten in Apple products now sourced from 100 percent recycled material. This helps Apple achieve its aim of using only recycled and renewable materials in all products, and moves it closer to its 2030 target of zero carbon emissions.

By 2025, Apple aims to use entirely recycled rare earth elements in magnets for its devices. In 2022, Apple increased its use of 100 percent certified recycled rare earth elements from 45 percent to 73 percent, with plans to use it in all magnets in iPhone, iPad, Apple Watch, MacBook, and Mac models. This will soon make nearly all rare earths in Apple products 100 percent recycled.

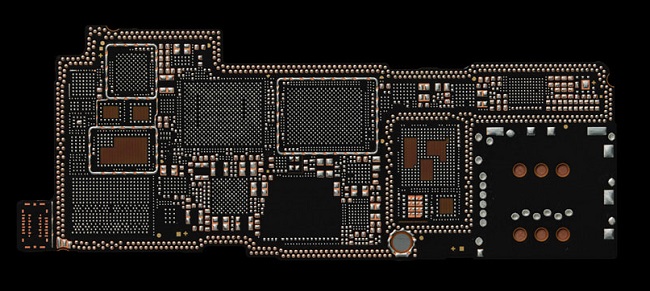

Apple is committed to using 100 percent certified recycled gold plating on all its printed circuit boards by 2025. This includes rigid and flexible boards in iPhone, iPad, Apple Watch, AirPods Pro, MacBook Pro, Mac mini, and HomePod.

Apple has already extended the use of recycled gold in various components and products, including the wire of all cameras in the iPhone 14 lineup, and is also working to promote the adoption of recycled gold in the electronics industry.

Apple aims to use only certified recycled tin soldering on all its circuit boards by 2025. Apple has already increased its use of recycled tin in the solder of flexible printed circuit boards across its products, with 38 percent of all tin used in 2022 coming from recycled sources. Apple is working to use recycled tin in more parts and involve more suppliers in this work.

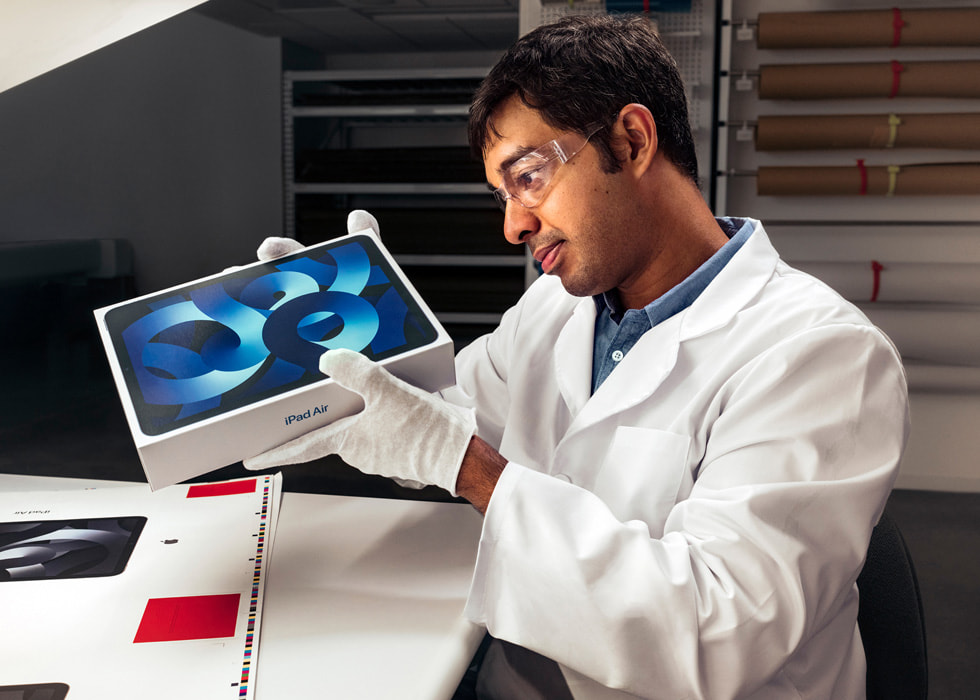

Plastics Elimination: Apple is committed to eliminating plastics from its packaging. The development of fiber alternatives for packaging components has helped Apple make progress towards this goal. Apple printed on iPhone 14 and 14 Pro boxes directly in 2022, removing most labels.

It also used a new varnish instead of plastic lamination for iPad Air, iPad Pro, and Apple Watch Series 8 boxes. These improvements have prevented more than 1,100 metric tons of plastic and more than 2,400 metric tons of carbon dioxide.

Apple has made significant progress towards its sustainability goals, including increased use of recycled metals, rare earth elements, gold plating, and tin soldering in its products.

The company is also actively working towards eliminating plastics from its packaging. These efforts demonstrate Apple’s commitment to environmental sustainability and its aim to make its products more sustainable and environmentally friendly.

Apple is reducing its reliance on newly mined minerals and supporting communities dependent on mining. Partnerships with organizations like the Fund for Global Human Rights provide support for human rights and environmental defenders in regions like the African Great Lakes. Apple also invests in vocational education programs to help local communities transition away from mining.

Apple ensures responsible sourcing of primary minerals across its supply chain. It was the first electronics company to publish lists of cobalt and lithium refiners in its battery supply chain. Since 2015, all identified smelters and refiners for tin, tungsten, tantalum, and gold have participated in independent audits.

Transition to Recycled and Renewable Materials

Apple prioritizes 14 materials, accounting for nearly 90 percent of materials shipped in its products, based on environmental, human rights, and supply impact. In 2022, approximately 20 percent of materials in Apple products came from recycled or renewable sources. This includes the use of recycled copper foil, certified recycled steel, and 100 percent recycled tungsten in various Apple products.

Innovating for the Future of Recycling

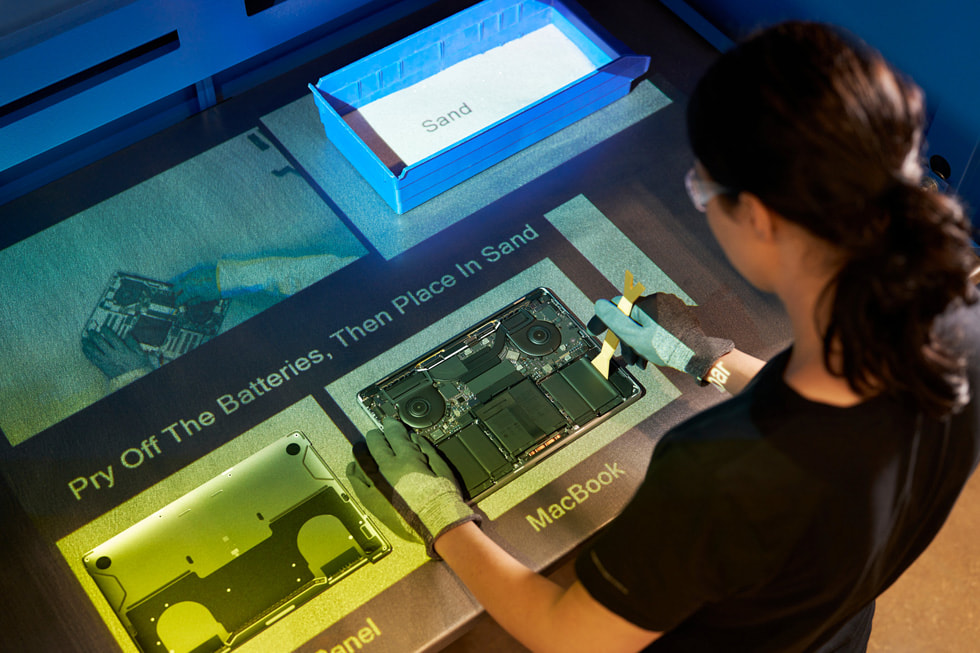

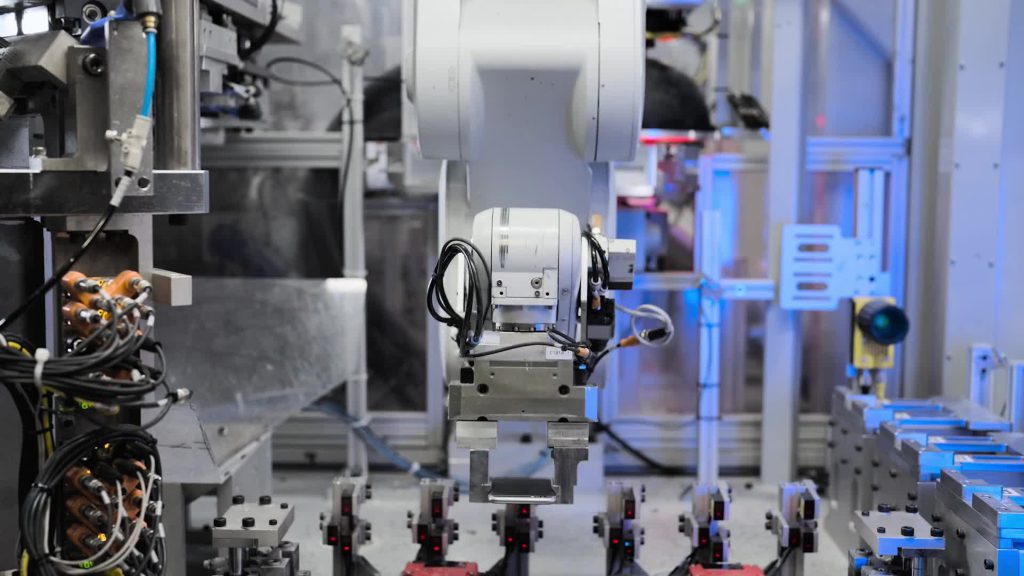

Apple leads the way in finding new ways to take apart and reuse its products when they are no longer needed. Its iPhone disassembly robot, Daisy, recovers materials such as cobalt and lithium from batteries, estimated to be over 11,000 kilograms of cobalt since 2019. The company’s Dave robot in China further accelerates recovery of rare earth elements.

Apple deploys augmented reality systems to guide device disassembly and publishes recyclers guides for efficiency and safety. Enhanced material recovery contributes to Apple’s goal of being carbon-neutral across its supply chain and product life cycle by 2030.

Speaking on the announcement, Tim Cook, Apple’s CEO, said:

Apple makes technology that helps people and the planet. Our products are recycled and our operations are green. We care about the environment and our users.

Commenting on the announcement, Lisa Jackson, Apple’s vice president of Environment, Policy, and Social Initiatives, said,

We want to use only recycled and renewable materials in our products and make them carbon neutral by 2030. We’re working hard and leading the way for our industry.